GWM and Bosch have joined forces to create a benchmark factory for intelligent manufacturing with collaboration of "Lighthouse Factory" project.

Project Background

In response to the national strategic target of gradually realizing Industry 4.0, and to build a benchmark factory that can fully realize intelligent manufacturing and enhance the brand value and influence of GWM, GWM and Bosch signed a "Lighthouse Factory" cooperation project in June 2021 to be implemented in the second-phase body-in-white workshop of GWM's Xushui plant. Bosch Rexroth welding team collaborated with the GWM body-in-white workshop's process and production team to optimize the welding process and complete the commissioning work that meets the evaluation standards of a Lighthouse Factory.

About "Lighthouse Factory"

A "Lighthouse Factory" refers to a real production factory that has scaled the application of the Fourth Industrial Revolution technologies and successfully moved from a pilot phase to a large-scale integration phase. "Lighthouse Factories" have achieved remarkable results in the integrated application of cutting-edge technologies of the Fourth Industrial Revolution, realizing significant financial and operational benefits, and are leading enterprises that serve as global models.

Customer Introduction

About GWM

GWM was founded in 1984 and headquartered in Baoding City, Hebei Province. The company has gradually developed into a flagship Chinese SUV manufacturing brand, with more than 40 holding subsidiaries and over 70,000 employees. It has eight major domestic vehicle production bases and possesses independent supporting capabilities for core components such as engines and transmissions. It has been continuously selected as one of the Top 500 Chinese Enterprises, Top 10 Chinese Private Listed Companies, and the leader of the Top 100 Enterprises in Hebei Province, becoming one of the most outstanding national auto brands. It owns five brands: Haval, WEY, ORA, TANK, and Great Wall Pickup, with products covering three major categories: SUV, sedan, and pickup truck.

Global Manufacturing Footprint

In addition to its eight major production bases in China, GWM has also established KD factories in countries such as Ecuador, Malaysia, Tunisia, and Bulgaria.

Product Introduction

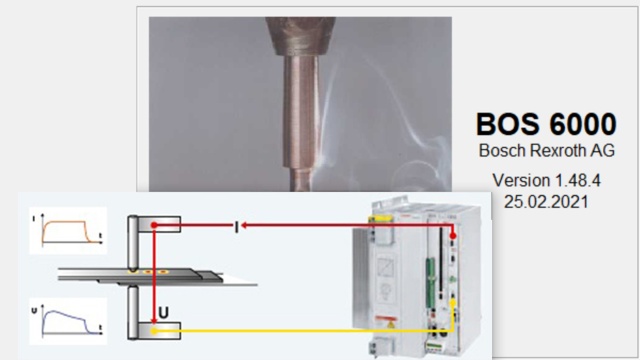

Bosch Rexroth has developed a medium-frequency welding controller that meets the manufacturing requirements of GWM's car bodies manufacturing requirements. Our advanced controller not only has welding functions such as welding point programming, electrode maintenance, dressing tool management, part number recording, sheet thickness and pressure management, and fault code output in the body spot welding process, but is also supplemented by Bosch Rexroth's medium-frequency adaptive welding function to monitor the energy of the weld nugget and ensure the quality control of the entire welding process.

Bosch Rexroth not only brings a high-quality product experience to GWM but is also committed to using its industry experience to help GWM establish process documents and databases that meet its own welding production requirements.

Client Benefits

During the spot welding process, various unavoidable interferences such as gaps, shunts, and changes in welding position and posture can affect the total resistance of the welding circuit, leading to fluctuations in the energy of the weld nugget. With Bosch Rexroth's adaptive technology, you can monitor resistance fluctuations throughout the welding process and make adjustments and compensations in welding current and time to ensure the energy and strength requirements of the weld nugget during its formation.